Prototype Development and the Design Process

Prototyping Physical Products

An effective product development process cannot exist without prototyping. It’s not uncommon for entrepreneurs and product managers to assume they’re entirely separate disciplines but, in practice, there is always an element of prototyping involved in any design undertaking. Prototypes can take many forms depending on the context but, in general, we define a prototype as any preliminary model or representation of a concept. If that sounds vague, it’s because they can take on many different forms. For example, a prototype of a webpage might be a series of images stitched together in a Powerpoint slide, whereas a prototype of a cell phone case might be a to-scale model produced by a 3D printer for ergonomic testing. Whether we’re designing services, apps, physical products, or strategy, prototypes continually serve as invaluable tools for testing and improving upon design concepts.

Another common misconception is that prototyping is a fixed step in the design process. In reality, it’s not a gate that a product must pass through prior to final production but, rather, a recurring activity in the product development cycle. This article is intended to be an introduction to the process, methods, and different prototyping tools that are instrumental in developing early representations of physical products.

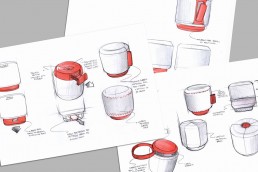

Mock-ups and Early Prototype Development

When designing physical products, mock-ups are usually the earliest form of a prototype produced. These mock-ups can be made from virtually any material such as clay, foam, wood and are great for getting a sense of overall size, shape, and function. Many ergonomic issues are tested and worked out in this stage and it serves as a great opportunity to get hands-on feedback before going too deep into the development process. Mockups are generally the most basic form of prototyping with the lowest cost and yet, it’s very critical not to overlook its importance. This is often the stage where crucial learnings lead to meaningful tweaks and refinements which ultimately inform a better user experience. Successful product design teams and agencies often spend a considerable amount of development time on mockups and use this form of prototyping to expedite their problem-solving processes.

3D Printed Prototypes

No article about prototyping can be complete without mentioning one of the most popularized terms in product development, 3D Printing. While the technology may not be in the homes of millions of consumers as predicted a decade ago, it plays an important role throughout the prototyping process. Sometimes designers use it to create early versions of complex components, while in other instances the technology can output parts that make their way into high fidelity and functional prototypes. At Shape, we 3D print both plastic and metal components for different applications. In short, 3D printing is an additive manufacturing process through which a physical object is created from a three-dimensional digital model. The printer works by depositing successive layers of hot plastic one at a time from the bottom up. Since it is an automated process and the materials are relatively inexpensive, 3D printing serves as a great way tool to produce early prototypes. It allows for much more accurate form representation while not requiring a high level of fabrication skills from designers. Depositing one thin layer at a time, however, is a very time-consuming process and output speed is what has held the technology back from revolutionizing the world of manufacturing. The layers are also visible to the naked eye and require extensive manual labour for a polished result. Because of this, 3D printed components are generally used to test ergonomics and functionality but not buyer-facing elements of higher fidelity prototypes. Depending on the size and complexity and strength requirements of the part being prototyped, 3D printing can be an alternative for hand-making mockups or it can be used in a secondary phase of prototyping after refinements stemming from initial mockup testing have been made.

Design Iteration and Refinement

After testing initial mockups and learning about how the conceptual dimensions translated to the real world, design teams generally jump back into CAD modeling and translate analog findings to their digital models. Having a more informed view of the whole product experience can help steer the product into a more refined state but it can also shed light on major design changes that can improve the product experience. It’s very important to enter into this prototyping stage with an open mind and being willing to learn and take a few steps back if needed. Remember that mock-ups are to test and expose flaws in the design, not to stroke the ego. A mockup that doesn’t lead to at least minor iterations is more often the result of oversight, not proof that the design was perfectly thought through on the first go.

High Fidelity and Functional Prototypes

After several phases of crude prototypes and design refinements, design teams generally move into high fidelity and functional prototyping. These prototypes can serve a number of different purposes but, most often, they’re produced nearing the end of the design process and are meant to be the near-final representation of the product before it goes into production. Whereas early prototypes are meant to be cheap and easy, higher fidelity prototypes are more about showing the design elements from a visual and mechanical perspective. As such, they require a higher level of attention to detail and demand more complex and laborious production methods. Rather than employing the additive process of 3D printing, higher fidelity prototypes often use subtractive manufacturing processes like CNC machining. CNC machining starts with a block of material that is shaped by a number of cutting and spinning tools. This process results in much better dimensional accuracy and can be used with metals, plastics, and wood. Because the process starts with a solid block of material, the final result is generally much stronger and smoother than what can be achieved with a 3d printer. Some materials can’t be CNC’d or 3D printed and need to be injection molded. To avoid the cost and timelines of steel molds, aluminum and silicone molds are often used. For a deeper dive into the different forms of tooling, we recommend checking out our article on different forms of tooling.

After the components have been produced, higher fidelity prototypes generally go through much more post-processing than the models produced at earlier stages in the design process. Different paints and finishes are applied here to better represent what the final production of the product will look like.

Choosing the Right Prototyping Process

In crowdfunding campaigns, we often see the use of high-fidelity non-functional prototypes paired with descriptions of how the product will work once it’s finished. There is nothing inherently wrong with non-functioning prototypes for this purpose as long as the concept has been proven through a semi-functioning prototype somewhere along the process. All too often, we see new entrepreneurs jump into crowdfunding campaigns with very conceptual prototypes that haven’t been properly tested and thought through. While the bold claims and product photography might be enough to secure initial orders, the conceptual nature of the design makes it impossible for factory teams to provide an accurate quote and, if the time finally comes, entrepreneurs usually find that the product is riddled with production issues.

Ultimately, there is no single prototyping process that we can recommend in an article. The outcome of our product development process is a unique solution and, by nature, can’t be standardized. The needs of the entrepreneur launching a crowdfunding campaign, for example, will be completely different from the needs of a Fortune 500 brand that has already allocated budget for production and marketing. Reputable design agencies and capable teams will work with their stakeholders to understand needs and develop a prototyping plan that supports their go-to-market strategy. They recognize that, while a prototype is often set out as a deliverable, the act of prototyping is really a crucial element of developing more impactful products and should happen throughout the entire design process.

Designing Long-Term Care Facilities

COVID-19’s impact on LTC Facilities

Even months into the COVID-19 pandemic, without proper documentation and tracking of national data on COVID-19 cases, it’s hard to get a comprehensive view of who, where, and how citizens are currently being affected. In one of the unfinished first passes of reporting to the Centers for Medicare & Medicaid Services (CMS), deaths caused by Covid-19 within Long-Term Care (LTC) facilities are reported to account for somewhere between 30-40% deaths in the US. As told by the former head of the CDC on CNN on March 8th, “One thing stands out as the virus spreads throughout the United States: nursing homes and other long-term care facilities are ground zero”. For those who are familiar with the LTC system in the US, no one is surprised by why so much of the Covid-19’s death count appears to occur in these spaces. It is not just a matter of who is compromised by age; it is a systemic issue that many experts saw coming years ago.

The hopeful prospect of this pandemic is that it shows us where our limitations are. As the numbers grow and we continue to fight through this pandemic, it will prompt us to take a long, hard look at how we treat our aging population in need of assisted living services. The Medicare and Medicaid system does not cover the cost of most if any of the skilled labor and facilities needed for assisted living or long-term care. Many seniors of the middle class are forced to impoverish themselves to simply qualify for Medicaid alone and this says nothing of out of pocket expenses that are incurred from paying for services as older adults. We are living in an aging nation and the number of older adults over 65 projected to increase from 15.2% to 23.4% by 2060. This rising demographic does not receive its primary care from hospitals or physicians. Rather, they rely on the work of nurses, personal support workers, home care, nursing homes, and assisted living facilities.

“While the aging of America’s population has been foreseen for decades, little has been done to prepare the health and long-term-care workforce for it’s arrival.” – National Academy of Medicine

Systematically speaking, America does not care for older adults and that is laid bare in facilities of care that are understaffed, undertrained, and undersupplied; all of which are exacerbated by the pandemic. This also feeds into the expansion of privatization in LTC facilities in the US which further widens the disparity between wealthy and poor older adults whose care is now jeopardized by their ability to pay.

With the government making emergency stop-gap solutions for the lack of staffing, supplies, and general support in such facilities, it raises the question of what will happen after COVID-19. When we have time to bounce back, what will we have learned from this pandemic and what can we do differently? With any hope, it means we will see an honest effort made to put more funding into the care of older adults and more creative ideas put into action for what we can do to improve the design of LTC facilities.

Redesigning long term care

Residents in LTC facilities are currently feeling more trapped than ever. As self-isolation has become a mandatory requirement among the residents of these facilities, their routine has been stripped down to daily meals left at their door and minimal interactions with staff and other residents. While there are clear physical risks for older adults venturing outside their rooms, there are also psychological repercussions to being confined to small spaces. Depression and loneliness were issues among older adults long before COVID-19 and are only made worse in our present position. Amidst the pandemic, our team took to coming up with some ideas that, we hope, will be implemented into the design of future LTC facilities.

How can we bring back meaningful in-person connections while still practicing proper social distancing?

Re-Designing LTC Floor Plans

Reorganizing LTC floor plans to cluster resident rooms into smaller pods and have their doors facing each other means that residents can still maintain daily in-person interactions with each other even through the confines of their rooms. Residents would be able to stay within a reasonable distance of each other while still being able to interact with one another in the pod-like layout of the floor, rather than having floor plans with straight and narrow halls with successive rooms one after the other.

Safer Doorway Interactions

We will not always be in a state of pandemic, but it will be important to prepare for those situations. Interactions have become more limited to the space surrounding resident doorways. How can we improve upon that space for interaction and make it a more lasting and enjoyable space for interaction? Introducing Dutch doors will help encourage more interaction from the confines of their rooms, but still offer a physical barrier that helps residents keep a safe distance towards others. Including additions like a folding table can help transform the space into a more enjoyable place for sustained periods of time. For times of more heightened safety precautions, a protective screen can be added to help safeguard other residents and workers while still helping encourage interaction.

Purposeful Wandering

Video chats have become a vital part of how we interact now and are critical for those living in LTC facilities. We should find ways of encouraging movement with these virtual visits to add a more physical element to them. This type of activity is typically conducted while sitting in place and it would be an interesting idea if we could flesh out this experience to be more dynamic for those involved. This would help encourage physical activity and help with the simulation of in-person interactions with loved ones. Using the familiar design of an IV drip stand, we can repurpose this to carry tablet displays while users can travel and walk alongside their virtual visitors with assisted stability. We can also design a tablet mounting system that attaches to an assistive walker, so users are able to use their walkers during a virtual visit. While this has implications for possible points of distraction and injury if users are not careful, with the right safety measures, this could have the potential to provide a new dimension to physical activity, virtual interactions, and personal independence for older adults that can perform these activities on their own.

The design and improvement of LTC facilities is not a new proposition, but we are currently living in a time of radical change and it offers the opportunity to look at the problem in new ways. Ageism is an issue in the US and so is the undervaluing of aging services. Policy development and lack of funding reflects our cultural attitudes. There is nothing glamorous about well-designed, pandemic-resistant nursing homes and there is no political or social price to pay for pushing long-term care down the priority list, but with the number of fatalities climbing among older adults we can’t ignore these issues. As designers we have the responsibility as innovators to make the distinction between what is exciting and what is important to talk about, because there is room for innovation in both. There is not enough media attention in the design sphere for LTC facilities to pull focus into these less glamorous subjects. We have the power as designers to help draw attention and bring excitement to these kinds of subjects if we would take the time. So I offer the question: What could Covid-19 mean for LTC facilities?

- How can we learn from the weaknesses we have seen over the past months?

- What is missing and can be improved?

- How do we look at these issues as opportunities for innovation?

- How can we help older adults be more active, social, provide necessary, or be more independent, without the spread of disease?

10 Best Books for Designers in 2020

Our favorite product design books

Without the hours spent piloting our vehicles to the design studio, our podcast consumption has dropped considerably and we’ve been missing the voices of other design thought leaders. On the bright side, however, we’ve managed to squeeze in more armchair time and have rediscovered the books that first inspired us to pursue careers in design along with some new ones to expand our thinking. Below is a list of what we consider to be the top 10 books for aspiring product designers to read in 2020, whether you’re an industrial designer working to develop physical products or a digital product designer crafting on-screen interactions. This list is far from comprehensive but reading ten books before the end of the year is ambitious enough on its own so we’ll save some additional titles for our 2021 list.

Note: Shape is NOT an affiliate with any of the links below. We’re sharing these strictly because we think they’re awesome reads.

The Art of Innovation

by Tom Kelley

We will always jump at the chance to get an inside look at an inspirational design company like IDEO. Kelley strongly believes that everyone can be creative, and between IDEO and the d.school at Stanford, his work over the past 3 decades has been about making innovation a way of life. This book tells stories directly from IDEO while also drawing upon learnings from other leading companies.

The War of Art

by Steven Pressfield

Do you ever sit down at your desk in front of a blank screen only to realize you’re thirsty or that you need to check your inbox for… anything else? This is what Steven Pressfield calls the resistance. The War of Art is an insightful and entertaining book to keep close to your desk and prompt you to jump into the struggle we all must deal with while trying to produce great creative work.

Tom Peters Essentials: Design

by Tom Peters

Tom Peters is a management thinker most known for his 1982 classic, In Search of Excellence. His own search for excellence has led him to become a very vocal ambassador for design. Design is a short book, or perhaps a rant, about why design must be at the heart of every business, and it’s one we highly recommend.

The Laws of Human Nature

by Robert Greene

In order to develop a deep understanding of our users, it’s insightful to strengthen our understanding of human behavior. The Laws of Human Nature provides profound observations seen through the lens of history, psychology, and philosophy. If the author’s name rings a bell, it’s likely because you’ve heard of his previous bestseller, The 48 Laws of Power.

Purple Cow

by Seth Godin

Like Tom Peters, Seth Godin doesn’t come from a design background. Rather, he’s a management thinker on a pursuit to inspire people to do work that matters. Purple cow is a book about creating products and services that are worth marketing in the first place. If that isn’t enough to perk a designer’s ears up, the cover also features some praise from Tom Kelley.

Creative Confidence

by Tom Kelley, David Kelley

Where The Art of Innovation is more about building innovative teams and organizations, Creative Confidence focuses on how each of us can unleash our own creative powers. While this book has major appeal to those outside of the design industry who are looking to be more creative, it also provides an action plan for designers to boost their ability to innovate. As Tom Peters praised “Don’t just read it. Use it. Now.”

Objects of Desire: Design and Society Since 1750

by Adrian Forty

Objects of Desire is a very consumable book filled with brilliant insights from the past 200 years of design and manufacturing. In his book, Forty shows how much truly goes into the design of objects all around us. Written in 1992, Objects of Desire has retained its relevance as a thought-provoking look at how design and society intertwine.

The Design of Everyday Things

by Don Norman

The Design of Everyday Things is quite possibly the most well known and applicable book on the topic of product design. Whether you’re an industrial designer or UX designer, Don’s six fundamental principles of design likely have vast implications on the work you do. It’s an insightful piece on the psychology behind product interaction and one that should be on every product designer’s bookshelf.

Hooked: How to Build Habit-Forming Products

by Nir Eyal

In Hooked, Nir Eyal draws upon principles of cognitive psychology and decision making to analyze why some products capture our attention while others flop. The result is a how-to guide for building better products and doesn’t require you to pour over hours of abstract theory. This book is geared more towards the UX design community, but delivers valuable insights for industrial designers as well.

Emotional Design

by Don Norman

In his second book on our list, Norman explains how the principles of human psychology inform the invention and design of the new products that surround us. Going beyond his claim that a user’s needs should trump a designer’s aesthetic, Norman argues that human centered design is about creating effective tools that mesh with human emotion.

Reading the way to better design

Rereading some of the older books on this list recently, we were surprised by how relevant they still are despite having been written before the advent of the iPhone. The creative challenges faced by Da Vinci in 1502 as he designed an odometer are not unlike the design challenges we face today. It all comes back to designing experiences that will delight the people who use them. The best way to design better for people is to learn more about them, and we hope that this list serves as a great place to get started.

What the Amazon affiliate rate cut means for your brand

What changed with Amazon’s affiliate program

In mid-April, Amazon made significant cuts to commission rates for members of its affiliate marketing program. Commission revenue through affiliate links is a major source of revenue for many online media entities from independent bloggers to major publications like CNET. If you’re not familiar with this type of marketing strategy, an affiliate program is a performance-based marketing initiative where an external partner (affiliate) is paid a commission for helping an online store generate sales. When you watch a video for “the ten best Bluetooth speakers under $50” there’s a good chance that the links in the description help the channel earn a commission for each sale generated. Here’s an example of affiliate links in a Youtube description:

Why the change matters for your brand

If you’re reading this, you’re most likely not a Youtube influencer who’s just had your revenue model slashed by 50-80%, so why should you care? For brands, the biggest impact will be seen in the second and third-order consequences of this action. For the past decade, affiliates have been responsible for generating a significant percentage of sales across a wide range of e-commerce platforms and have become a major component of many PR strategies. Brands have reaped the rewards from this as publications and influencers have considered product reviews to be valuable content. They can help generate direct revenue for the publication while also providing their readers with interesting content that encourages more time spent on-page. This time-on-page also helps boost ad revenue for the publication.

Seeing their revenue drop by as much as 80% in some categories will force these affiliates to re-evaluate their content plans and start looking for alternative revenue generation opportunities. While product reviews generate visits and will never completely dry up, with the revenue-generating potential of a “The ten best Bluetooth speakers under $50” now cut by up to 50-80%, we’re likely to see a significant drop in these types of posts as bloggers and media entities look for better ways to generate revenue.

As the supply of reviews shrinks, established brands and commodity amazon sellers alike will soon need to find alternative ways to generate brand awareness and drive traffic to product pages. An added layer of complexity is that, with consumers in North America confined to their homes, many traditional brand activation campaigns are on hold and the bricks and mortar locations that served as an additional source of revenue are closed, putting increased pressure on non-essential consumer product brands.

What we can learn

It will be interesting to see the chain reaction that this commission rate cut and more interesting to see how product marketers respond. Either way, we hope that it serves as an important reminder of the fragility of building livelihoods upon the platforms of others. When we learn to rely on Amazon’s referral program to generate sales on Amazon’s storefront that are then shipped through Amazon’s warehouse with Amazon’s logistics fleet, we might find ourselves becoming overly reliant on a system that we cannot control. How can we make sure we’re not leaving our brands in a vulnerable position? In addition to diversifying our contact points with consumers, it’s important to remember the value created by a relationship that extends beyond a single transaction.

What can’t be easily taken away from you is the benefit of brand recognition and the attention and respect you earn from your audience by consistently providing value to them and following through on your promises. Yes, a Google or Instagram algorithm might change overnight, making your message harder to find but if you’ve left your customers or audience with a reason to connect with you and enough places to do so, they will.

COVID-19: Perspective in a Pandemic

Product design comes from the unleashing of creative thinking based on an immediate need. It comes from within but is very much influenced by everything we see, hear, touch and experience. It has been this way since the beginning of time really.

As I sit here writing this, I have a torn ACL, torn MCL, and a fractured tibia. The damage was done over a month ago and there is no option for medical treatment at all. It’s not a medical emergency and in the larger scheme of things with what is happening locally and around the world, it is now seemingly insignificant. Before this COVID-19 outbreak, it would have been a different story and garnered much more attention.

The point is, as humans we focus our energy and effort on the biggest challenge or threat that we face at any given time. In the world of product design, it’s no different. When all is well in the world, we focus on creating products with new innovative features and functionality. Better, stronger, faster….more is better! We create brands with stories and beautiful elaborate packaging that offers a great “unboxing experience” for the consumer. For decades we have been spoiled. We live life in an effort to improve our surroundings and make a better world for our children. In the process, however, we seem to have focussed so much on ourselves. Me, me, me. Bigger homes, nicer cars with fancy new technology and features. More color options, more channels, on-demand. More frequent travel to explore all ends of the earth while still maintaining all the creature comforts we have come to enjoy as spoiled humans. Yep, we have slowly gotten so accustomed to “on-demand” products and services that we have slowly lost touch with the fundamentals of life. In an effort to make life easier and allow us to have more conveniences and more free time, we have actually created a world where we have less time. We are always connected with technology and are burdened with “things”. Rather than freeing ourselves in body and mind to truly live, we have essentially become prisoners of our own making. As a product designer, I can’t help but think about this.

It usually takes a very substantial event to hit home with us and make us re-evaluate life and what it’s really all about. For some, it’s a close call with an illness, maybe the death of a loved one or the loss of a limb. Perhaps a natural disaster. For society as a whole, it can be a world war or a pandemic. Something big….. really big. Bigger than all of us. Something that makes us all change our fundamental thinking and how we approach or lives each day.

Our studio is relatively small. Small enough that we were able to react and respond quickly to the pandemic. We made some quick changes and for over a week now, we have all been working independently off-site in our homes, away from the design studio. It does come with some challenges in communication, but nothing that we cannot adapt to. We had a video conference call as a group on Monday morning to touch base and review the many projects on our plates. It was exciting to see the faces of the team that I have missed seeing in the studio during this time of self-isolation. Yet another reminder that it’s not just about the projects or the products we design. Behind those products is a team of real people. People who see, hear, feel and experience life with friends and loved ones.

In a post-COVID-19 era, I have no doubt that our approach to product design will be modified.

Our thinking will most certainly have more of a global outlook that asks critical questions about the validity of what we are designing. We will be more experienced, more understanding and perhaps more humble in our views. There have been some very eye-opening moments over these past few weeks. Moments where we can all do some self-reflection and look at ways to truly focus on how we can all contribute to a better world, whether through product design or any other endeavour. Going forward, those efforts will surely have more purpose and meaning.

After the dust has settled from the COVID-19 pandemic, the world will be changed. It will surely be a different place with new challenges and renewed focus. I am a firm believer in the notion that through overcoming challenges and difficulty, we gain valuable insight and experience. The type of insight that leads to the creation of more meaningful products. Products that are designed with purpose and meaning. I am personally looking forward to the next chapter and am ready to take it on with renewed energy and an open mind.

What is tooling?

What is tooling?

To put it simply, tooling is the backbone of the physical production of a product. Much like how you could not make muffins without a muffin tin, many consumer products need their own version of a “muffin tin” in order to be mass-produced. For many, this is the non-glamourous side of production but without it, products simply do not exist. The term “tooling” refers to any number of implements required to produce a product.

Injection Mold

This is one of the most common forms of tooling. Most commonly, this will be a block of steel or alloy that is precision machined as a negative of the part being produced. In it’s simplest form, it is a two part core & cavity the closes up with hydraulic pressure. A hopper filled with plastic pellets is melted and injected into the cavity under high pressure to take the shape of the part being produced within the mold. Once cooled, the two halves of the mold are separated and the plastic part is ejected from the mold. There is always some post-processing that takes place to remove any bits of plastic from the injection point but essentially, once it is out of the mold, the part is ready for assembly or post-processing which can include painting, chrome plating, or printing with additional elements like a company logo etc. This is how pen caps, food storage containers and your key FOB are produced.

Blow Mold

This is another common form of tooling and one that is simpler in construction than an injection mold because it only requires a cavity and no core. This type of tool is also precision machined from a block of steel or alloy to create a negative of the part being produced. In production, The two halves of the blow mold cavity come together to pinch a curtain of melting plastic, trapping it within mold. A small injector (essentially a needle) also trapped between the two halves, blasts air into the middle of the curtain of melting plastic, sending it outward against the walls of the mold to take the shape of the final product. Once cool, the mold opens up and the part is ejected with a hollow inside. This is how pop bottles, water jugs and oil bottles are produced.

Rotational Mold (Roto Mold)

This is somewhat similar to a blow mold in construction but the process is quite different. With this type of tool, the two cavities come together with a pre-measured quantity of plastic pellets inside the mold. The mold is then heated while being rotated on multiple axis until the plastic with the mold melts and coats the inside of the mold. The process or “cycle time” is much longer than blow molding but it is well suited to producing very large parts and parts that require a thicker wall. This is how some kayaks are made as well as large water holding tanks, children’s playground sets etc.

In its most basic sense, a tool is simply a working or manufacturing aid that is required to make a product or part. They can include dies, gauges, molds, jigs, and cutting equipment. While tools can be used for general purposes (cutting equipment and screwdrivers) in the case of most of our clients, when manufacturers are referring to tooling, it’s generally in a highly specialized sense – as one of the molds mentioned above.

Should this Exist? A short guide to evaluating your idea’s worth

Should this exist?

In our past two decades of helping our clients launch new brands and build upon existing ones, we’ve observed some factors that increase the likelihood of an idea being adopted in the marketplace. If taking note from our clients wasn’t enough, we’ve even decided to introduce a few products of our own. What’s written here is not meant to be a comprehensive guide to launching your new idea but, rather, aims to help you explore the reality of your ah-ha! moment:

Should this exist beyond my imagination?

We don’t mean “should this exist” as a thought-provoking moral dilemma as is often the case on the popular new podcast sharing the title. No, what we’re asking here is, why is this idea worth pursuing? Is it worth the grueling hours that will need to get it off the ground? Is it worth sacrificing the time you could be doing something else? Is it worth the injected plastic that will, one day, end up in a landfill? Whenever we’re going through the process of launching something new, we always start by asking ourselves two important questions:

-

- Why should this be brought into the world?

- Is there an existing alternative that is already solving the problem we’re aiming to?

Why should this be brought into the world?

Rather than proposing elaborate new financial models to evaluate the revenue potential of your idea, our objective is simply to prompt you to think about a few key questions prior to committing your energy to chase after your new idea. For most people, the light bulb goes off when a personal need for something arises but, to be viable beyond a personal prototype, you’ll need more than one customer.

Fortunately, there’s never been a better time to launch an idea that connects with small, specialized audiences across the globe. The continual increase in free-flowing information paired with more efficient logistics infrastructure has made niche groups of consumers more accessible than ever. While specialized audiences may be spread thin geographically, they can often be found in tightknit groups online and generally like to share their experiences with the rest of the community. The caveat to this is that specialized groups of category enthusiasts tend to have stronger pre-existing brand loyalty, higher quality expectations, and are very quick to spot imposters who are just stopping by to make a quick buck. If your idea is meant to address the needs of a specialized niche group, authenticity had better be in your game plan.

Whether your idea is specialized or has mass market appeal, to introduce a new product and urge your customers to trade it for their hard earned cash, you’d better have a very compelling story. How is your idea going to contribute to the lives of those who use it? Like a new CRM tool for sales teams, does it help people do more with less? Or, like the output from the entertainment industry, is it based on making people feel good? If your idea doesn’t remove pain points or make a positive contribution to someone’s day, it’s probably time to head back to the drawing board. Unless you have a huge marketing budget to help introduce your idea to the world, you’ll need early support of advocates and this is only made possible by providing a remarkable customer experience. Why not do some preliminary exploration with a sample of your target market before launching headlong after your idea?. When we receive a slow nod and an “I might be interested in that” we know we’re in trouble. While presenting new ideas, we’re looking for jaw-dropping genuine excitement. During the early stages of whatever we’re working on, we refer back to the teachings of Seth Godin and ask ourselves the very basic; is this really worth talking about?

Competition – Do alternatives already exist?

After concluding that an idea has merit and is worth bringing into the world, it’s important to understand the alternatives that are already available. A quick google search is insightful and can help you understand if your new idea isn’t so new, but we advise you go beyond that and identify if there’s anything out there that solves the same problem you’re aiming to.

Access to sourcing websites like Alibaba, intuitive e-commerce platforms like Shopify and the speed at which we can now connect with freelancers on Upwork have made it easy to lay the groundwork of introducing something new to the world. A business can now be started in a local public library and requires little to no mastery. It’s important to remember that, as these barriers are eliminated for you, they’re also being eliminated for your potential competitors. As we continue to build platforms and tools that amplify noise, why is your idea going to stand out from the rest? Remember that long before you compete for sales, you will need to compete for your customer’s attention. Publishing an e-commerce website is one thing, but finding the people to visit it is where the required mastery has now shifted to.

In our years helping brands introduce new ideas and design new products, we’ve realized that there is a major misconception that being better is enough. Does your new knife stay sharp 15% longer than the leading brand at Target? Unfortunately, 15% is not worth a consumer’s cost of switching or the inconvenience it will cause the buyer to move something else off the shelf. Better is only enough when the odds are already in your favor and this isn’t likely to be the case. Often, you’ll find yourself up against brands that have been spending decades building retail relationships, reliable supplier networks, and international brand awareness. Whether it’s a consumer, buyer or investor, the gatekeepers you need to impress with your idea are already busy doing something else and you’ll need to find a way to get their attention. Once you have their attention, you will then need to convince them that your idea is worth the cost of switching. When it comes to launching new ideas in a crowded space, we advise innovators to aim to launch an idea that provides at least a 10X benefit over the next best thing.

Why 10X?

In his work, Understanding the Psychology of New-Product Adoption, John T. Gourville notes that consumers tend to overvalue products they already own by a factor of three while companies tend to overvalue their new products by a factor of three. As a result, there is a 9X mismatch about what developers think consumers want and what consumers actually want. This model uses only psychological biases and doesn’t take into consideration the market advantages possessed by pre-existing competition so we feel it’s safer to strive for a 10X improvement.

With this disconnect in mind, new ideas are likely to fall flat if they’re only 2 or 3X better than the entrenched market players. In order to negate the upper hand the existing competition holds and give an idea a chance to succeed, it needs to deliver substantial benefits. Bookstores already existed when Jeff Bezos decided to start one but he figured out a model that would allow Amazon to have 10x the offering. Dollar Shave Club may not have reinvented the razor, but the sum of experiences it offered consumers certainly hit the 10X marker and rattled the chains of major CPG (Consumer Packaged Goods) companies. How can you build upon your idea to ensure your competitors’ customers will look beyond the psychological costs of switching from what they’re already invested in?

Take a breath

The spark of a new idea is intoxicating and helps power entrepreneurs through the grueling early stages of development but these early stages require the discipline and humility to slow down and ask the tough questions. Whether you’re creating an entirely new category or diving into an older area filled with competition, in order to make it off the ground, new ideas need to be compelling and worth talking about. At this stage, it’s important to remember that we are all biased and are likely overweighing our idea’s benefits by a factor of three. Prior to taking on a new project, we work with our clients to dig deep and help answer two fundamental questions: Should this be brought into the world? And how can we make it at least 10X better than the next best alternative?

Rather than getting discouraged if your idea can’t pass this test, take a breath, head back to the drawing board and work on creating an idea for your users to love. Day in and day out, we work with brands to help them increase the likelihood that their ideas gain traction. If you’re in the early stages of ideation and need some fresh eyes, we’re here to help.

Your competition already has the upper hand. How are you going to take that from them?

List 4 of Section 301 Tariffs

Return to Tension

As trade relations between the U.S and China seem to be further deteriorating, importers are now at risk of facing a 25 percent tariff on over 3,700 products.

On May 13, the U.S Trade Representative (USTR) published its fourth list of proposed Section 301 tariffs on Chinese products imported into the U.S. The list covers $300 billion worth of Chinese imports. Prior to List 4, the Trump administration had tried to make the tariffs less painful to American shoppers by shielding consumer electronics but that is no longer the case. The newest list proposes a 25% tariff on daily use products like cellphones, televisions, clothing, housewares, pens, and strollers.

List 4 can be viewed here and includes most remaining U.S imports which have not been previously assessed Section 301 tariffs.

Tariff summary as of May 16, 2019

Warehousing - A guide to receiving, storing, and shipping your inventory

How to receive, store, and ship your products

If you’re planning on shipping a physical product to customers, you’re going to need a location to store your inventory. The type of location you choose will vary depending on the types of customers you need to ship to but, before we get into that, let’s define some of the different warehousing terms you may have come across so far:

Warehouse: A warehouse is a building that is used to store commercial merchandise. Warehouses generally act as longer-term storage solutions and are used by importers, exporters, and wholesalers/distributors. They’re equipped with loading docks so products can be shipped or received by transport trucks. Warehouses can be owned directly by a wholesaler or operated by a Third Party Logistics provider.

Third Party Logistics Facility (3PL): 3PL facilities are outsourced warehousing options used by the majority of Fortune 500 companies. These facilities can receive, hold, and transport products, but they never take possession (ownership) of the goods.

Distribution Center (DC): A distribution center is a specialized warehouse used for temporary storage and redistribution of goods. Mass retailers use a network of distribution centers as a storage center for retail locations to pull inventory from.

Key Warehouse Considerations

So, your product design is nailed down and your supplier is about to begin production but needs to know where it will be shipping the finished product. What’s next?

Shipment Volume

First, you will need to consider the volume of product you will be receiving. If you have a small business and only plan on receiving a few boxes of product at a time, a local storage facility or your parent’s garage might do just fine. If you plan on receiving pallets, containers, or truckloads, you will need access to a loading dock in a warehouse. Fortunately for small businesses, in North America, there are large networks of third-party logistics facilities that can receive, store, pack and ship your product for you. With these 3PL providers, you will pay a monthly storage fee (usually per pallet) while incurring variable charges for receiving and shipping your product. Many of these service providers work with all sorts of different small business and can provide a helping hand along the way.

Identifying key customers

The second variable to consider is who your customers are. Online sellers that are are shipping directly to consumers can often operate cost-effectively right out of their garages until the volume becomes too much to handle, Small businesses working with mass retailers, on the other hand, are often required to ship product on pallets which means they will need to have access to a shipping door at an owned warehouse or 3PL facility. To make your life easier, it will be important to select a 3PL provider that already has experience working with the retailers you will be shipping to. This can save time while avoiding financial penalties of improperly shipped product.

In the early stages of your business, it’s important not to overextend yourself. If you don’t yet need the services provided by a 3PL, there’s no harm in starting small in the space you already have (spare room, garage, ect). As the volume starts to pick up and you find yourself in a time crunch, it might be wise to consider moving your inventory to a 3PL facility or even moving into an office with warehousing space and loading docks while bringing on experienced personnel to manage the logistics side of your business.

Choosing a Storage Location

If you’ve decided that working with a 3PL facility is the best option for your business, the next step is determining the best location for your inventory to be stored. This requires a balance between proximity to supply and proximity to demand. Warehousing in the Los Angeles area can be a great option as it’s close to the shipping ports and provides a cost-effective option for receiving inventory from Asia, however, if the majority of your customers are on the East Coast, your FedEx bills will quickly erase any gains in freight savings. For our consumer brands with higher volume, we usually activate a 3PL facility on the East Coast and one on the West Coast. The price to get a container to the east coast is higher but we make up for it very quickly in savings on direct-to-consumer shipments.

Understand Your Costs

Every business has different needs and there are many factors to take into consideration when determining how to store and ship your products. Spend the time building out different models to give yourself a full understanding of where your costs will be coming from and where there are opportunities for increased efficiency. While it’s important to choose a solution that allows you to scale, remember not to overburden yourself so much early on that you don’t have the resources to invest in growing your business.

Shape Products wins Red Dot: Product Design award for TAP

Toronto – Shape Products Inc. has won a Red Dot award: Product Design 2019 for its work with TAP – wearable keyboard and mouse. TAP receives an Honourable Mention, which the renowned jury awards for particularly well-executed aspects of design work.

TAP partnered with Shape Products to design a new wearable keyboard and mouse that is multifunctional and intuitive. The final product is a game-changing wearable technology that turns any surface into a touch keyboard. This wearable technology with its ergonomic design is comfortable and straightforward to use. The design language for TAP embodies extensive research in materials to achieve a form function that is not only comfortable to wear but has a high level of input accuracy. The light-weight and minimal design makes it ideal for VR/AR applications, as well as for the visually-impaired audience.

On winning an honourable mention in the prestigious Red Dot Product Design category, Shape Products Inc.’s Founder and President – Ron Tsang, said, “We are ecstatic to receive such a world-renowned award. This recognition of our extensive work in TAP’s design and production of the final product is a fitting testament to Red Dot’s high standards. I would also like to congratulate our designers at Shape and partners at TAP for this remarkable achievement.”

“Shape Products understood our design challenge and was able to deliver a product design that complements the complex technology within TAP. A product design that is not only appealing, durable and comfortable to use but is also futuristic in its vision.” said Ran Poliakine, Co-founder, TAP.

The Red Dot Award: Product Design is one of the world’s largest design competitions. In 2019, designers and manufacturers from 55 countries entered more than 5,500 products in the competition. The international jury has been convening for more than 60 years to select the year’s best designs and comprises experienced experts from different disciplines. True to the motto “In search of good design and innovation”, their assessment focuses on criteria such as the level of innovation, functionality, formal quality, longevity and ergonomics.

On 8 July 2019, Shape Products will celebrate its success during the award ceremony in Essen’s Aalto-Theater as part of the Red Dot Gala. At the subsequent Designers’ Night party, the Honourable Mention laureates will receive their certificates and TAP will join the exhibition “Design on Stage” in the Red Dot Design Museum Essen, which presents all of the award-winning products. From that date, TAP will also be on show in the Red Dot Design Yearbook, online and in the Red Dot Design App.

About the Red Dot Design Award

In order to appraise the wide scope of design in a professional manner, the Red Dot Design Award is broken down into the three distinct disciplines: The Red Dot Award: Product Design, Red Dot Award: Brands & Communication Design and Red Dot Award: Design Concept. With more than 18,000 submissions, the Red Dot Award is one of the largest design competitions in the world. In 1955, a jury convened for the first time to assess the best designs of the day. The name and brand of the award were developed in the 1990s by Red Dot CEO, Professor Dr. Peter Zec. Since then, the sought-after Red Dot is the revered international seal of outstanding design quality. The winners are presented in yearbooks, museums and online.

Further information: www.red-dot.org.